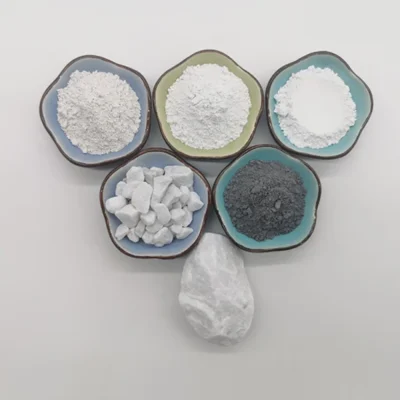

What is Drilling Barite?

Drilling Barite is a special type of mineral known as barium sulfate (BaSO4). This material, with its high specific gravity (around 4.2 to 4.5), is classified as a heavy material. The color of drilling barite can vary from white, gray, pink, or brown, with darker shades indicating more impurities.

Barite occurs naturally in the earth’s crust and appears in different forms such as massive, granular, radial, and concretionary. However, what makes it valuable to the oil and gas industry is its ability to increase weight.

What is Barite?

The name of this mineral is derived from the Greek word for “heavy.” Its specific gravity is around 4.5. This mineral, composed of BaSO4, belongs to the group of anhydrous sulfates. Barite is found in various forms such as massive, granular, radial, spherical, and concretionary. Its color ranges from white, blue, red, yellow, gray, brown, green, black, to colorless.

The Vital Role of Drilling Barite in the Oil and Gas Industry

Drilling oil and gas wells is a complex and sensitive operation. During drilling, engineers face various challenges, including high-pressure subsurface layers, removing drilled rocks (cuttings), and maintaining wellbore stability. In this scenario, drilling barite plays a key role as a critical component in the drilling fluid. Drilling fluid is injected into the well and performs numerous vital functions.

Formation Environment of Barite

Barite often occurs as a gangue mineral in hydrothermal veins and is associated with minerals such as galena, sphalerite, fluorite, siderite, hematite, and calcite. It also forms in stratiform deposits alongside sandstones, carbonate rocks, clays, and siliceous shales. These deposits are known as Mississippi Valley-type (MVT) deposits. Sometimes, it is deposited by hot springs activity.

In the massive sulfide deposits of the Kuroko type, which are of volcanic sedimentary origin, barite is seen in the upper and surrounding parts of the massive sulfide deposit. If barite-bearing rocks are weathered and eroded, barite remains due to its high specific gravity and chemical resistance, forming residual deposits. The barite grade in such deposits typically ranges between 10 and 20%. Over 80% of the world’s barite production is used as drilling mud in the drilling of oil and water wells.

Due to the high specific gravity of barite powder slurry, it forms a mud cake on the well walls, preventing the collapse of the well walls and allowing the suspended cuttings to be removed from the well. The purity of this product is between 92% and 94%.

This commodity is one of the main sources of barium for the chemical industry. The most common use of barium is in lithopone, a uniform mixture of barite and zinc sulfide. Lithopone is used as a pigment extender in the paint industry and in the textile industry. Precipitated barium sulfate is used as a filler in the garment and cosmetics industries and as a white pigment.

Barite Production in Countries Worldwide

In 1996, global barite production was approximately 4.5 million tons. The major producers include the United States, Germany, China, Canada, and several other countries. There are numerous barite mines in Iran, with about 20 active mines producing around 160,000 tons of barite annually for domestic and international markets.

Production of Barium-Containing Chemicals

The second major use of barite is as a source for producing barium-containing chemicals, which are widely used across various industries. Precipitated barium sulfate is used as a pigment extender in paints and as a filler in the paper, rubber, and linoleum industries. Barium chloride is used in leather tanning and textile manufacturing, and barium carbonate is used as a glaze in ceramic finishing.

Crushed Barite Applications

Crushed barite is directly used as a coating in rubber production and as a pigment extender in paints. If crushed barite grains are the size of coarse sand, they can be used in the glass industry, where barite acts as a flux, facilitates working on glass, and enhances transparency. Crushed barite is also used as a cement coating for underwater pipelines transporting oil and gas, primarily due to its weight and chemical inertness.

Technical Specifications of Drilling Barite

| Value | Parameter |

| 99.5 – 97% | (BaSO4) Purity |

| 4.1 – 4.3 g/cm³ | Specific Gravity |

| <0.5% | Fineness |

| <0.5% | Water Solubility |

| 7.0 – 9.0 | pH |

| <50 µS/cm | Electrical Conductivity |

| <1.0% | Moisture Content |

| <100 ppm | Chloride Content |

| <500 ppm | Iron Content |

| <50 ppm | Lead Content |

| <10 ppm | Cadmium Content |

| <50 ppm | Chromium Content |

| <50 ppm | Nickel Content |

| <10 ppm | Arsenic Content |

Uses of Drilling Barite and Applications of Barite

Barium oxides are used in the glass industry, electric furnaces, and metallurgy. Barium hydroxide is commonly used in refining and producing sugar from molasses, and barium nitrate is a component in flares and detonators. Barite also has secondary uses in various chemical compounds. About 10% of the world’s barite production is used to manufacture barium-containing chemicals.

Barite in Industries

- Rubber Manufacturing

- Paper Manufacturing

- Leather Manufacturing

- Glass Manufacturing (for clarity and brightness)

- Ceramics Manufacturing (as a glaze)

- Pesticide Production

- Asbestos

- Brake Pads

1- The Use of Barite in Oil and Gas Drilling

In deep oil and gas drilling, particularly in areas where the pressure of gas or liquid from below is high, heavy materials are required to manage the drilling process. Barite, due to its suitable properties, is used in such cases. Barite powder is added to standard water-based mud, and due to its beneficial characteristics such as weight, chemical inertness, cleanliness, and relatively low cost, it is highly favored.

Typically, three-quarters of the annual barite production is consumed in this sector. Barite is a vital mineral in the oil and gas drilling industry. According to 1980 statistics, about 90% of barite produced globally was consumed in drilling mud. Barite is used in drilling mud due to its high specific gravity, ease of use, chemical inertness, softness, and reasonable cost. The amount of barite consumed per kilometer of drilling is reported to be about 429 tons.

– Well Pressure Control

One of the most important functions of drilling barite is to control the pressure of the fluid inside the well. By increasing the specific gravity of the drilling fluid with barite, the hydrostatic pressure in the well increases. This hydrostatic pressure acts as a shield, preventing fluids from entering the well from subsurface formations and stopping oil or gas from escaping.

– Transportation and Removal of Drilled Rock Fragments

During drilling, rock fragments, called cuttings, are produced. These fragments must be continuously removed from the well to prevent blockages and slowdowns in the drilling process. Drilling barite, by increasing the density of the drilling fluid, helps transport these fragments more efficiently.

– Cooling and Lubricating the Drill Bit

The drill bit generates a significant amount of heat as it rotates and cuts through the earth. The drilling fluid containing barite is responsible for cooling and lubricating the drill bit, preventing it from wearing down or becoming damaged due to friction and excessive heat.

– Stabilizing the Wellbore Wall

Maintaining wellbore stability is one of the key challenges in drilling. Drilling barite helps by depositing on the wellbore wall, providing stability and strength. This prevents the wellbore from collapsing and reduces the risk of accidents.

– Preventing Oil and Gas Leaks

As previously mentioned, drilling barite increases hydrostatic pressure in the well, preventing oil and gas from leaking out. This not only helps protect the environment but also prevents the loss of valuable hydrocarbon resources.

2- The Use of Barite in Ceramics

In glass production, barite is used as a homogenizer of the molten material, reducing bubbles, and enhancing brightness and transparency. Glasses containing barium are clearer and more brilliant than those made with lead or calcium oxide. Advanced ceramics containing barium are used in the electronics industry (capacitors, phones, speakers) and in permanent magnets.

3- The Use of Barite in Fillers

In the paint, plastic, paper, and rubber industries, barite is used as a filler. Its high specific gravity also makes it useful in the production of cement blocks. A mixture of rubber, asphalt, and 10% barite is used to coat surfaces in parking lots, roads, and airports. Additionally, it is used in pharmaceuticals, explosives, alloys, radiation protection, and more.

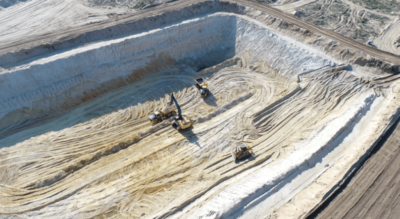

Barite Processing and Production for Drilling

The production of drilling barite involves several stages, including extraction, crushing, milling, impurity removal, and packaging.

– Raw Barite Extraction:

Raw barite is extracted from mines around the world. Different methods are used for mining barite, including open-pit mining, underground mining, and controlled blasting.

– Crushing and Milling of Barite:

Once extracted, the raw barite is transported to processing plants. In this stage, the barite is crushed into smaller pieces and then milled to produce barite powder.

– Impurity Removal Process:

Barite powder contains impurities such as rock, soil, and heavy metals. These impurities are removed through various processes like washing, cycloning, and magnetic separation.

– Packaging and Transport of Drilling Barite:

After processing and impurity removal, drilling barite is packaged in special bags and transported to its destination for use.

Types of Drilling Barite Based on Features

There are two main types of drilling barite:

- API Barite:

This type of barite is produced according to API (American Petroleum Institute) standards and is of high quality and grade. API barite is used in the drilling of deep and high-pressure oil and gas wells. - High Specific Gravity Barite:

As the name suggests, this type of barite has a higher specific gravity than API barite. It is used in drilling wells that require higher pressure control, such as deep-sea oil and gas wells.

Global Market for Drilling Barite

The global barite market is steadily growing in terms of volume and value. The increasing global demand for oil and gas is one of the main drivers of this growth. It is projected that by 2028, the global market for drilling barite will exceed 30 million tons.

Main Consumers of Drilling Barite:

- Oil and Gas Companies: The largest consumers of drilling barite are oil and gas companies active in the upstream sectors of the oil and gas industry.

- Drilling Companies: Drilling companies use drilling barite in the operations of drilling oil, gas, water, and geothermal wells.

- Other Industries: Other industries that use barite include paint manufacturing, ceramics, rubber, and glass.

Major Producers of Drilling Barite in the World:

- China: China is the largest producer of drilling barite globally, accounting for about 40% of the global market.

- India: India is the second-largest producer of barite, with approximately 20% of the global market.

- The United States: The U.S. is the third-largest producer of drilling barite, holding around 10% of the global market.

- Other Countries: Other barite-producing countries include Iran, Turkey, Morocco, Spain, Italy, Germany, Russia, and Australia.

Factors Influencing the Price of Drilling Barite

The price of drilling barite depends on various factors, including:

- Grade and Quality: The higher the grade and quality of the barite, the higher the price.

- Extraction and Processing Costs: Extraction and processing costs for barite depend on several factors, including the type of mine, extraction methods, processing technology, and energy costs.

- Transportation Costs: The cost of transporting barite from production to consumption sites is another factor influencing its price.

- Supply and Demand: Global demand for drilling barite and its supply by producers play a significant role in determining the price of this mineral.

The Future of Drilling Barite and Potential Alternatives

Despite the steady growth in demand for drilling barite, concerns remain about the environmental impact of its use. The extraction and processing of barite can lead to soil and water contamination, dust generation, and the release of greenhouse gases.

Research is ongoing to develop environmentally friendly alternatives to drilling barite. Some of these alternatives include:

- Nanoparticles: Nanoparticles of silica and clay can be used as alternatives to drilling barite in drilling fluids.

- Synthetic Resins: High-density synthetic resins may be used as substitutes for barite in certain applications.

While research is underway to find eco-friendly alternatives for drilling barite, it is unlikely that this mineral will be completely replaced. Barite offers unique advantages, such as high specific gravity, chemical stability, and a competitive price, making it an ideal material for use in drilling fluids.

However, it is expected that in the future, the use of barite alternatives will increase alongside barite. This is especially evident in areas with significant environmental concerns, such as coastal and protected areas.

Additionally, technological advancements in drilling may reduce the need for drilling barite. For example, the development of dry drilling methods could significantly reduce the need for drilling fluids.

In conclusion, the future of drilling barite depends on several factors, including technological advancements, environmental concerns, and the cost of alternative materials.

Buying and Selling Drilling Barite at Part Energy Group

Part Energy Group is one of the active companies in the field of buying and selling minerals and drilling barite in Iran. With a proven track record in this area, Part Energy Group proudly offers a wide range of high-quality drilling barite to its customers across various industries, especially the oil and gas sector.

The drilling barite products offered by Part Energy Group include:

- API Barite

- High Specific Gravity Barite

- Special Purpose Barite: Part Energy Group also offers drilling barite with specific technical specifications tailored to meet the needs of its clients.

Advantages of Purchasing Drilling Barite from Part Energy Group:

- High Quality

- Competitive Prices

- Wide Range of Products

- Excellent Customer Service

For more information about the products and services provided by Part Energy Group, you can contact the company’s experts.

Reviews

There are no reviews yet.