Description

Lime, or calcium hydroxide, is a white, odorless powder with the chemical formula Ca(OH)₂. It is produced by hydrating calcium oxide (quicklime) and is known for its strong alkaline properties. In drilling operations, lime is utilized in both water-based and oil-based drilling fluids to perform several vital functions that enhance drilling efficiency and wellbore integrity.

Functions and Benefits:

- pH Control and Alkalinity Maintenance:Lime is primarily used to increase and maintain the pH of drilling fluids. A higher pH environment helps in stabilizing the drilling fluid and prevents the corrosion of drilling equipment. By providing excess alkalinity, lime acts as a buffer, ensuring that the pH remains within the desired range throughout the drilling process.

- Emulsion Stability in Oil-Based Muds:In oil-based drilling fluids, lime plays a crucial role in stabilizing water-in-oil emulsions. It reacts with fatty acid emulsifiers to form calcium soaps, which enhance the stability of the emulsion. This stability is essential for maintaining the rheological properties of the mud and ensuring efficient drilling operations.

- Neutralization of Acidic Gases:Lime is effective in neutralizing acidic gases such as hydrogen sulfide (H₂S) and carbon dioxide (CO₂) that may be encountered during drilling. The reactions are as follows:

- Ca(OH)₂ + H₂S → CaS + 2H₂O

- Ca(OH)₂ + CO₂ → CaCO₃ + H₂O

By neutralizing these gases, lime helps in preventing their hazardous effects on both the drilling equipment and personnel.

- Calcium Ion Provision:Lime serves as a source of calcium ions (Ca²⁺) in the drilling fluid. These ions are essential for various chemical reactions within the mud system, including the activation of certain polymers and the stabilization of shale formations.

- Control of Bentonite Hydration:In water-based muds, the presence of calcium ions from lime can suppress the excessive hydration of bentonite clay. This control over hydration helps in maintaining the desired viscosity and gel strength of the drilling fluid.

- Improvement of Filter Cake Quality:The addition of lime can enhance the quality of the filter cake formed on the wellbore walls. A thin, impermeable filter cake is desirable as it minimizes fluid loss into the formation and prevents differential sticking of the drill string.

Application Guidelines:

- Concentration:The typical concentration of lime in drilling fluids varies depending on the specific requirements of the drilling operation. In oil-based muds, an excess lime content of 3 to 5 lb/bbl is commonly maintained to ensure emulsion stability and provide a buffer for acidic gas neutralization. In scenarios where high concentrations of H₂S or CO₂ are anticipated, the excess lime content may be increased to 5 to 10 lb/bbl to effectively neutralize these gases.

- Addition Method:Lime should be added slowly to the drilling fluid system to prevent localized high pH zones, which can lead to the precipitation of other additives or the destabilization of the emulsion. Proper mixing equipment should be used to ensure uniform dispersion of lime throughout the mud system.

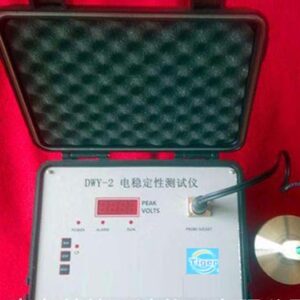

- Monitoring:Regular monitoring of the drilling fluid’s pH, alkalinity, and calcium content is essential to maintain the desired properties. Field tests such as the phenolphthalein alkalinity test (Pₐ) and the filtrate calcium test can be employed to assess the alkalinity and calcium levels, respectively.

Safety and Handling:

Lime is a caustic substance and should be handled with care. Personal protective equipment (PPE) such as gloves, safety goggles, and protective clothing should be worn to prevent skin and eye contact. In case of contact, the affected area should be rinsed thoroughly with water. Adequate ventilation should be ensured to avoid inhalation of lime dust. Spills should be cleaned promptly to prevent slippery conditions. Always refer to the Safety Data Sheet (SDS) for detailed safety and handling instructions.

Reviews

There are no reviews yet.